Ford OHV engine / transmission reconnection and refitting - is a part of Ford repair manuals: Ford OHV Engines. This part contains the detailed description and diagrams for Ford OHV engine/transmission reconnection and refitting. This is a direct reversal of the removal and separation from the transmission. Take care not to damage the engine ancillary components and body panels when raising the unit into position.

Reconnection.

Reconnection of Ford OHV engine and transmission is a reversal of separation but if the clutch has been dismantled, check that the driven plate has been centralised, and that the pressure plate bolts are tightened to the specified torque. Locate Ford OHV engine bearer and mountings and tighten the attachment bolts and nuts.

Refitting.

First check that Ford OHV engine sump drain plug is tight and that the gearbox cap nut (removed to drain the oil) is refitted, together with its locking pin and spring. Manoeuvre Ford OHV engine/transmission under the vehicle and attach the lifting hoist.

Raise the engine carefully until the engine mounting stud is engaged in the suspension strut retaining plate and the engine bearer is in contact with the floorpan. Align the engine bearer with the retaining bolt holes then fit and tighten the bolts. When tightening the bolts check that the mounting rubbers are not being twisted. Refit the transmission bearer to the rubber insulator, fit the right-hand mounting retaining nut and washer, the side-mounted bolt and washer (under the wheel arch) and tighten. With Ford OHV engine and transmission fully secured, release the lifting hoist and remove it. If some sort of plug was used to prevent the differential pinion cage from turning, remove the plug now. If a plug was not used, insert a finger in the driveshaft hole and align the cage ready to receive the driveshaft. If this is not done, the driveshaft cannot engage with the splined pinion gear.

Raise the engine carefully until the engine mounting stud is engaged in the suspension strut retaining plate and the engine bearer is in contact with the floorpan. Align the engine bearer with the retaining bolt holes then fit and tighten the bolts. When tightening the bolts check that the mounting rubbers are not being twisted. Refit the transmission bearer to the rubber insulator, fit the right-hand mounting retaining nut and washer, the side-mounted bolt and washer (under the wheel arch) and tighten. With Ford OHV engine and transmission fully secured, release the lifting hoist and remove it. If some sort of plug was used to prevent the differential pinion cage from turning, remove the plug now. If a plug was not used, insert a finger in the driveshaft hole and align the cage ready to receive the driveshaft. If this is not done, the driveshaft cannot engage with the splined pinion gear.

Use a new snap-ring and reconnect the right-hand driveshaft to the transmission by having an assistant apply pressure on the roadwheel. Check that the snap-ring has locked in position. Relocate the right-hand tie-bar and bracket to the crossmember and refit the retaining bolts. Reconnect the right-hand lower suspension arm. Tighten the bolts. Refit the driveshaft and suspension lower arm to the opposite side in a similar way to that just described. Rotate the gearchange housing back through 180° then loosely attach it to the floor panels with the retaining bolts. Reconnect the transmission stabilizer rod, making sure to insert the washer between the rod and the transmission case. Check that the gearchange rod is still in 4th (4-speed gearbox) or reverse (5-speed gearbox). Tighten the gearbox housing-to-floor attachment bolts. Check that the contact faces of the gearchange rod and selector shaft are free of grease then reconnect them and adjust as follows, according to gearbox type:

Use a new snap-ring and reconnect the right-hand driveshaft to the transmission by having an assistant apply pressure on the roadwheel. Check that the snap-ring has locked in position. Relocate the right-hand tie-bar and bracket to the crossmember and refit the retaining bolts. Reconnect the right-hand lower suspension arm. Tighten the bolts. Refit the driveshaft and suspension lower arm to the opposite side in a similar way to that just described. Rotate the gearchange housing back through 180° then loosely attach it to the floor panels with the retaining bolts. Reconnect the transmission stabilizer rod, making sure to insert the washer between the rod and the transmission case. Check that the gearchange rod is still in 4th (4-speed gearbox) or reverse (5-speed gearbox). Tighten the gearbox housing-to-floor attachment bolts. Check that the contact faces of the gearchange rod and selector shaft are free of grease then reconnect them and adjust as follows, according to gearbox type:

Ford four-speed gearbox - pre 1987 models:

Ford four-speed gearbox - pre 1987 models:

- pull downwards on the gearchange rod and slip it onto the selector shaft which projects from the transmission; the clamp should be loose on the gearchange rod;

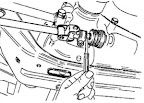

- using a 3.5 mm diameter rod or pin, insert it as shown and pull the gear lever downwards to lock it in the selector slide; when inserting the rod, point up upward to feel the cut-out in the gear lever before prising it downwards. Now turn your attention to the gearbox;

- using a pin or rod, inserted into the hole in the end of the projecting selector shaft, turn the shaft clockwise to its stop and retain it in this position with a strong rubber band. Now tighten the clamp pinch-bolt.

Ford four-speed gearbox - post February 1987 models:

Ford four-speed gearbox - post February 1987 models:

- set the gearchange lever inside the car to 2nd gear;

- free the control rod (which runs from the floor lever) from the selector rod at the transmission, by unscrewing the clamp bolt;

- make up a stepped rod similar to the one shown; this can be achieved by pushing a piece of welding rod through a length of plastic tubing;

- insert the tool into the left-hand side of the mechanism housing under the car, and feel the point of the tool engage in the hole in the lever arm; fit the O-ring or heavy rubber band as shown;

- with 2nd gear correctly engaged, reconnect the control rod to the selector rod by tightening the clamp bolt; remove the stepped tool;

- select each gear in turn to confirm that the linkage has been correctly set.

Ford five-speed gearbox - pre 1987 models:

Ford five-speed gearbox - pre 1987 models:

- use a lock tool similar to that shown, pull the gear lever down in its selector gate reverse gear position and set the tool to hold it against the stop;

- insert a suitable rod or drift into the hole in the selector shaft, rotate the shaft clockwise until it is felt to be against the stop then push it into the gearbox and retain it in this position while tightening the gearchange rod clamp bolt; remove the drift and lock tool.

Ford five-speed gearbox - post February 1987 models:

- set the gearchange lever inside the car to 4th gear;

- release the control rod (which runs from the floor lever) from the selector rod at the transmission by unscrewing the clamp bolt;

- insert a rod (3.5 mm diameter) into the left-hand side of the mechanism housing under the car;

- with the 4th gear correctly engaged, reconnect the control rod to the selector rod by tightening the clamp bolt; remove the temporary rod;

- select each gear in turn to confirm that the linkage has been correctly set.

Refit the clutch housing cover plate and secure with retaining bolts. Refit the starter motor and reconnect its wiring. Reconnect the engine earth strap underneath also the reversing light lead. Refit the exhaust system and bolt the downpipe to the manifold. Refit the heated air box which connects with the air cleaner. Reconnect the clutch operating cable. Reconnect the electrical leads, the fuel pipe, the brake vacuum hose and the speedometer cable.Reconnect the throttle cable and the heater hoses. Reconnect the radiator coolant hoses. Fill up with engine oil, gearbox oil and coolant, then reconnect the battery. Refit the bonnet, bolting the hinges to their originally marked positions. Fit the air cleaner and reconnect the hoses and the air cleaner inlet spout. Once the engine is running, check the dwell angle, timing, idle speed and mixture adjustment. If a number of new internal components have been installed, run the vehicle at restricted speed for the first few hundred miles to allow time for the new components to 2A bed in. It is also recommended that with a new or rebuilt Ford OHV engine, the engine oil and filter are changed at the end of the running in period.

Refit the clutch housing cover plate and secure with retaining bolts. Refit the starter motor and reconnect its wiring. Reconnect the engine earth strap underneath also the reversing light lead. Refit the exhaust system and bolt the downpipe to the manifold. Refit the heated air box which connects with the air cleaner. Reconnect the clutch operating cable. Reconnect the electrical leads, the fuel pipe, the brake vacuum hose and the speedometer cable.Reconnect the throttle cable and the heater hoses. Reconnect the radiator coolant hoses. Fill up with engine oil, gearbox oil and coolant, then reconnect the battery. Refit the bonnet, bolting the hinges to their originally marked positions. Fit the air cleaner and reconnect the hoses and the air cleaner inlet spout. Once the engine is running, check the dwell angle, timing, idle speed and mixture adjustment. If a number of new internal components have been installed, run the vehicle at restricted speed for the first few hundred miles to allow time for the new components to 2A bed in. It is also recommended that with a new or rebuilt Ford OHV engine, the engine oil and filter are changed at the end of the running in period.

from Ford repair manuals