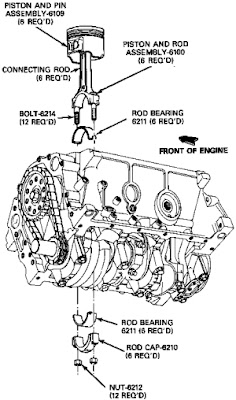

Ford Aerostar connecting rod bearings removal and installation - is a part of Ford Aerostar repair manuals: Engines. This part contains the detailed description and diagrams for Ford Aerostar with 2.3l, 2.9l, 3.0l and 4.0l engines.

Ford Aerostar connecting rod bearings are a selective fit to provide for necessary operational clearances and oil pressure. Refer to Ford Aerostar repair manuals: Engine Service, Gasoline, to measure bearing clearances and selection of the proper bearing insert. This operation is performed easiest with engine out of the vehicle. However, it can be performed with the engine in the vehicle.

Ford Aerostar connecting rod bearings removal:

- Disconnect negative battery terminal and set aside.

- Remove all six spark plugs to allow for uninhibited crankshaft rotation.

- Raise vehicle.

- Remove oil pan as outlined.

- Remove oil pump assembly if required.

- Turn crankshaft until connecting rod from which the bearings are to be removed is at the lowest point of travel.

- Loosen retaining nuts and remove from cap. Place retaining nuts so that they may be reinstalled on the same rod bolt.

- Tap cap with a plastic mallet to separate from connecting rod. Carefully remove cap from crankshaft. If lower bearing remained on crankshaft, carefully grasp both sides and remove (oil acts as an adhesive between two precision fitted components). Use extreme care to not scratch crankshaft journal.

- Install protective rubber caps onto connecting rod bolts to protect crankshaft journal from bolt threads. Protective caps may be made from rubber fuel line.

- Remove upper bearing insert. Push piston up enough to grasp bearing. If bearing remained on crankshaft, allow bearing to remain in contact with crankshaft journal and carefully rotate to bottom side of journal. Using care, remove bearing from crankshaft.

- Inspect bearings, crankshaft journal and connecting rod bearing surfaces for damage or wear.

Ford Aerostar connecting rod bearings installation:

- Lightly oil all bolt and stud threads before installation.

- Lightly oil all bolt and stud threads before installation.

- Thoroughly clean bearing inserts (including new bearings), connecting rod cap and connecting rod with solvent.

- Contaminants allowed to remain on the cap or bearing can distort the bearing or damage the crankshaft journals.

- Clean crankshaft journal and lubricate with Oil Conditioner D9AZ-19579-CA (ESR-M99C80-A) or equivalent heavy engine oil. Make sure the entire journal is well lubricated.

- Install upper bearing insert in the connecting rod. Align locating tab with relief in connecting rod and seat fully into the rod. Lubricate bearing surface with Oil Conditioner D9AZ-19579-CA (ESR-M99C80-A) or equivalent.

- Carefully pull rod down until it seats onto the crankshaft journal.

- Install bearing insert into rod cap. Align locating tab to relief in cap. Lubricate bearing surface with Oil Conditioner D9AZ-19579-CA (ESR-M99C80-A) or equivalent.

- Remove protective rubber caps from rod bolts.

- Install connecting rod cap and the retaining nuts.

- Connecting rods and caps are matched to each other. Never mix connecting rod caps between other connecting rods! Match code letters stamped on the side of cap and connecting rod so that they are both on the same side. Tighten retaining nuts to 35 N-m (25 ft-lb).

- Install oil pump assembly if removed. Align intermediate shaft with distributor shaft, align pump with dowels and install retaining bolt. Tighten to 48 N-m (35 ft-lb).

- Inspect and clean oil pump intake screen.

- Install oil pan and new gasket as outlined.

- Lower vehicle.

- Install spark plugs. Tighten to 11 N-m (8 ft-lb).

- Add correct amount and viscosity engine oil.

- Connect negative battery cable.

- On vehicles equipped with EEC, when the battery has been disconnected and reconnected, some abnormal drive symptoms may occur while the EEC processor relearns its adaptive strategy. The vehicle may need to be driven 10 miles or more to relearn the strategy.

- Disconnect ignition coil wire. Crank engine for 15 seconds to re-establish oil to oil pump assembly and bearing surfaces.

- Connect ignition coil wire.

- Start engine and check for oil leaks.

from Ford Aerostar repair manuals