Ford Mondeo engine repair manuals - is a part of Ford Mondeo repair manuals: Engines. This part contains the detailed description of Ford Mondeo in-car engine repair procedures and Ford Mondeo engine removal and general engine overhaul procedures with engine diagrams for Ford Mondeo with four-cylinder petrol engines, including special/limited editions (1597cc, 1796cc, 1988cc), Diesel and V6 engines.

Ford Mondeo in-car engine repair procedures:

- general information;

- repair operations possible with the engine in the vehicle;

- compression test - description and interpretation;

- engine lubrication system;

- Top Dead Centre (TDC) for No 1 piston - locating;

- cylinder head - removal and refitting;

- inlet manifold - removal and refitting;

- exhaust manifold - removal, inspection and refitting;

- crankshaft pulley - removal and refitting;

- timing belt covers - removal and refitting;

- timing belt - removal, refitting and adjustment;

- timing belt tensioner and toothed pulleys - removal, inspection and refitting;

- camshaft oil seals - renewal;

- camshafts and hydraulic tappets - removal, inspection and refitting;

- sump - removal and refitting;

- oil pump - removal, inspection and refitting;

- oil cooler - removal and refitting;

- oil level sensor - removal and refitting;

- oil pressure warning light switch - removal and refitting;

- crankshaft oil seals - renewal;

- flywheel / driveplate - removal, inspection and refitting;

- engine / transmission mountings - inspection and renewal.

Ford Mondeo engine removal and general engine overhaul procedures:

- general information;

- engine overhaul - general information;

- engine / transmission removal - methods and precautions;

- engine / transmission - removal and refitting;

- engine overhaul - dismantling sequence;

- cylinder head - dismantling;

- cylinder head and valve components - cleaning and inspection;

- cylinder head - reassembly;

- piston/connecting rod assemblies - removal;

- crankshaft - removal;

- cylinder block/crankcase - cleaning and inspection;

- piston / connecting rod assemblies - inspection;

- crankshaft - inspection;

- main and big-end bearings - inspection;

- engine overhaul - reassembly sequence;

- piston rings - refitting;

- crankshaft - refitting and main bearing running clearance check;

- piston/connecting rod assemblies - refitting and big-end bearing running clearance check;

- engine - initial start-up after overhaul.

Ford Mondeo four-cylinder petrol engine

Ford Mondeo engine, also known by Ford's internal code name "Zetec", is of four-cylinder, in-line type, mounted transversely at the front of the vehicle, with the (clutch and) transmission on its left-hand end.

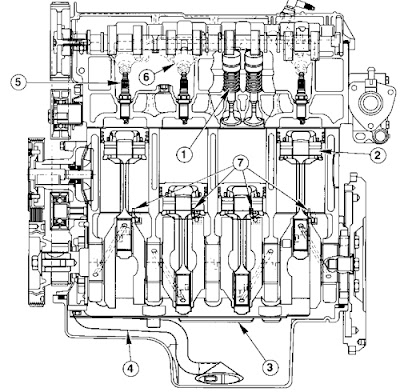

Ford Mondeo longitudinal cross-section through engine (inset showing timing belt details):

Ford Mondeo longitudinal cross-section through engine (inset showing timing belt details):

1 - inlet camshaft; 2 - exhaust camshaft; 3 - oil galleries; 4 - exhaust port; 5 - oil strainer and pick-up pipe; 6 - oil baffle; 7 - crankshaft; 8 - piston-cooling oil jet (where fitted); 9 - inlet valve; 10 - inlet port; 11 - fuel injector; 12 - inlet camshaft toothed pulley; 13 - timing belt; 14 - exhaust camshaft toothed; 15 - timing belt (front) guide pulley; 16 - crankshaft toothed pulley - behind; 17 - crankshaft pulley; 18 - oil cooler (where fitted); 19 - timing belt (rear) guide; 20 - timing belt tensioner.

Apart from the plastic timing belt covers and the cast-iron cylinder block/crankcase, all major engine castings are of aluminium alloy. The crankshaft runs in five main bearings, the centre main bearing's upper half incorporating thrustwashers to control crankshaft endfloat. The connecting rods rotate on horizontally-split bearing shells at their big-ends. The pistons are attached to the connecting rods by gudgeon pins which are an interference fit in the connecting rod small-end eyes. The aluminium alloy pistons are fitted with three piston rings: two compression rings and an oil control ring. After manufacture, the cylinder bores and piston skirts are measured and classified into three grades, which must be carefully matched together, to ensure the correct piston/cylinder clearance; no oversizes are available to permit reboring. The inlet and exhaust valves are each closed by coil springs; they operate in guides which are shrink-fitted into the cylinder head, as are the valve seat inserts. Both camshafts are driven by the same toothed timing belt, each operating eight valves via self-adjusting hydraulic tappets, thus eliminating the need for routine checking and adjustment of the valve clearances. Each camshaft rotates in five bearings that are line-bored directly in the cylinder head and the (bolted-on) bearing caps; this means that the bearing caps are not available separately from the cylinder head, and must not be interchanged with caps from another engine. The water pump is bolted to the right-hand end of the cylinder block, inboard of the timing belt, and is driven with the power steering pump and alternator by a flat polyvee-type auxiliary drivebelt from the crankshaft pulley. When working on this engine, note that Torx-type (both male and female heads) and hexagon socket (Allen head) fasteners are widely used; a good selection of bits, with the necessary adaptors, will be required, so that these can be unscrewed without damage and, on reassembly, tightened to the torque wrench settings specified.

Ford Mondeo engine overhaul

It's not always easy to determine when, or if, Ford Mondeo engine should be completely overhauled, as a number of factors must be considered. High mileage is not necessarily an indication that an overhaul is needed, while low mileage doesn't preclude the need for an overhaul. Frequency of servicing is probably the most important consideration.

Ford Mondeo lateral cross-section through engine:

Ford Mondeo lateral cross-section through engine:

1 - exhaust valve; 2 - piston pipe; 3 - oil baffle; 4 - oil strainer and pick-up; 5 - spark plug (where fitted); 6 - fuel injector; 7 - piston-cooling oil jets.

Ford Mondeo engine that's had regular and frequent oil and filter changes, as well as other required maintenance, will most likely give many thousands of miles of reliable service. Conversely, a neglected engine may require an overhaul very early in its life. Excessive oil consumption is an indication that piston rings, valve seals and/or valve guides are in need of attention. Make sure that oil leaks aren't responsible before deciding that the rings and/or guides are worn. Perform a cylinder compression check to determine the extent of the work required. Loss of power, rough running, knocking or metallic engine noises, excessive valve train noise and high fuel consumption rates may also point to the need for an overhaul, especially if they're all present at the same time. If a full service doesn't remedy the situation, major mechanical work is the only solution. Ford Mondeo engine overhaul involves restoring all internal parts to the specification of a new engine. During an overhaul, it is usual to renew the piston rings, and to rebore and/or hone the cylinder bores; where the rebore is done by an automotive machine shop, new oversize pistons and rings will also be installed - all these operations, of course, assume the availability of suitable replacement parts. The main and big-end bearings are generally renewed and, if necessary, the crankshaft may be reground to restore the journals. Generally, the valves are serviced as well, since they're usually in less-than-perfect condition at this point. While the engine is being overhauled, other components, such as the starter and alternator, can be renewed as well, or rebuilt, if the necessary parts can be found. The end result should be an as-new engine that will give many trouble-free miles. Before beginning the engine overhaul, read through the entire procedure to familiarise yourself with the scope and requirements of the job. Overhauling an engine isn't difficult, but it is time-consuming. Plan on the vehicle being off the road for a minimum of two weeks, especially if parts must be taken to an automotive machine shop for repair or reconditioning. Check on availability of parts, and make sure that any necessary special tools and equipment are obtained in advance. Most work can be done with typical hand tools, although a number of precision measuring tools are required, for inspecting parts to determine if they must be replaced. Often, an automotive machine shop will handle the inspection of parts, and will offer advice concerning reconditioning and replacement. As a general rule, time is the primary cost of an overhaul, so it doesn't pay to install worn or sub-standard parts. As a final note, to ensure maximum life and minimum trouble from a rebuilt engine, everything must be assembled with care, in a spotlessly-clean environment.

from Ford Mondeo repair manuals