Ford CVH engine cylinder head removal and refitting - is a part of Ford repair manuals: Ford CVH Engines. This part contains the detailed description and diagrams for Ford CVH engine cylinder head removal and refitting.

Ford CVH engine cylinder head removal:

- disconnect the battery earth lead;

- remove the air cleaner and detach the connecting hoses;

- remove the air cleaner and detach the connecting hoses;

- drain the cooling system;

- disconnect the coolant hoses from the thermostat housing;

- disconnect the coolant hoses from the automatic choke (if necessary);

- disconnect the throttle cable from the carburettor;

- disconnect the fuel pipe from the fuel pump;

- disconnect the vacuum servo pipe from the inlet manifold;

- disconnect the leads from the coolant temperature sender, the ignition coil, and the anti-run-on (anti-diesel) solenoid valve at the carburettor;

- unbolt the exhaust downpipe from the manifold by unscrewing the flange nuts;

- support the exhaust pipe by tying it up with wire;

- release the alternator mounting and adjuster link bolts, push the alternator in towards the engine and slip the drivebelt from the pulleys;

- unbolt and remove the timing belt cover;

- unbolt and remove the timing belt cover;

- slacken the belt tensioner bolts, lever the tensioner to one side against the pressure of the coil spring (if fitted) and retighten the bolts;

- with the timing belt now slack, slip it from the camshaft sprocket;

- disconnect the leads from the spark plugs and unscrew and remove the spark plugs;

- remove the rocker cover;

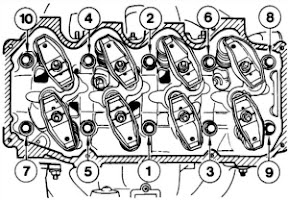

- unscrew the cylinder head bolts, progressively and in the reverse sequence to that given for tightening;

- discard the bolts, as new ones must be used at reassembly;

- remove the cylinder head complete with manifolds;

- use the manifolds, if necessary, as levers to rock the head from the block;

- do not attempt to tap the head sideways off the block, as it is located on dowels, and do not attempt to lever between the head and the block, or damage will result.

Ford CVH engine cylinder head refitting:

- before installing the cylinder head, make sure that the mating surfaces of head and block are perfectly clean with the head locating dowels in position;

- clean the bolt holes free from oil;

- clean the bolt holes free from oil;

- in extreme cases it is possible for oil left in the holes to crack the block;

- turn the crankshaft to position No 1 piston about 20 mm (0.8 in) before it reaches TDC;

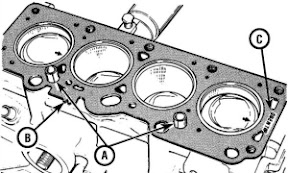

- place a new gasket on the cylinder block;

- the upper surface of the gasket is marked OPEN-TOP;

- note that from 1986 onwards, the configuration of the holes on the cylinder head gasket have been gasket is used for each size of engine;

- identification is by teeth on the rear facing edge of the gasket, as shown, according to engine type as follows: 1.6 litre 4 teeth, 1.4 litre 2 teeth;

- locate the cylinder head on its dowels and install and tighten the new cylinder head bolts, tightening them in four stages;

- after the first two stages, the bolt heads should be marked with a spot of quick-drying paint so that the paint spots all face the same direction;

- now tighten the bolts (Stage 3) through 90° (quarter turn) followed by a further 90° (Stage 4);

- tighten the bolts at each stage only in the sequence shown before going on to the next stage;

- if all the bolts have been tightened equally, the paint spots should now all be pointing in the same direction;

- fit the timing belt;

- refitting and reconnection of all other components is a reversal of dismantling;

- refill the cooling system.

from Ford repair manuals