Ford OHV engine repair manuals - is a part of Ford repair manuals: Engines. This part contains the detailed description and diagrams for Ford OHV engine repair procedures. Contents:

- general information;

- operations possible without removing OHV engine from vehicle;

- operations only possible with engine removed from vehicle;

- cylinder head - removal and refitting;

- valve clearances - adjustment;

- sump - removal and refitting;

- rocker gear - dismantling and reassembly;

- crankshaft front oil seal - renewal;

- pistons / connecting rods - removal and refitting;

- oil filter and pump - removal and refitting;

- engine / transmission mountings - removal and refitting;

- engine / transmission - removal and separation;

- engine - dismantling;

- engine - examination and renovation;

- cylinder head and pistons - decarbonising;

- engine - reassembly;

- engine / transmission - reconnection and refitting.

Ford OHV engine general information.

Ford OHV is of an overhead valve type based upon the "Kent" design used in many earlier Ford models. It is mounted transversely at the front of the vehicle together with the transmission to form a combined power train.

Ford OHV is a water-cooled, four-cylinder in-line type, having overhead valves operated by tappets, pushrods and rocker arms. The camshaft is located within the cylinder block and chain-driven from the crankshaft. A gear on the camshaft drives the oil pump and the distributor, whilst a cam operates the fuel pump lever.

The cylinder head is of crossflow type, having the exhaust manifold mounted on the opposite side to the inlet manifold. The crankshaft runs in three main bearings, with endfloat controlled by semi-circular thrustwashers located on either side of the centre main bearing.

The oil pump is mounted externally on the cylinder block just below the distributor, and the full-flow type oil filter is screwed directly into the oil pump.

Operations possible without removing Ford OHV engine from vehicle.

The following work can be carried out without having to remove Ford OHV engine: - cylinder head - removal and refitting; - valve clearances - adjustment; - sump - removal and refitting; - rocker gear - overhaul; - crankshaft front oil seal - renewal; - pistons / connecting rods - removal and refitting; - engine mountings - renewal; - oil filter - removal and refitting; - oil pump - removal and refitting.

Operations only possible with Ford OHV engine removed from vehicle.

The following work should be carried out only after Ford OHV engine has been removed from the vehicle: - *crankshaft main bearings - renewal; - crankshaft - removal and refitting; - **flywheel - removal and refitting; - **crankshaft rear oil seal - renewal; - camshaft - removal and refitting; - timing gears and chain - removal and refitting.

Although it is possible to undertake the job marked * without removing Ford OHV engine, and those marked ** by removing the transmission, such work is not recommended and is unlikely to save much time over that required to withdraw the complete engine / transmission.

Ford OHV engine cylinder head - removal and refitting.

Removal:

- open the bonnet and fit protective covers to the front wing upper surfaces;

- open the bonnet and fit protective covers to the front wing upper surfaces;

- disconnect the battery earth strap; it is as well to remove the battery, so that no metal objects are placed across its terminals;

- remove the air cleaner unit;

- drain the cooling system; note that the coolant should have an antifreeze solution mix and can be used again, so drain into a suitable container for re-use;

- disconnect the hoses from the thermostat housing;

- detach the choke cable;

- release the throttle cable from the carburettor operating lever by moving the spring clip and removing the bracket fixing bolt;

- disconnect the fuel and vacuum pipes from the carburettor;

- disconnect the breather hose from the inlet manifold;

- on vehicles with servo-assisted brakes, disconnect the vacuum hose from the inlet manifold;

- disconnect the HT leads from the spark plugs;

- disconnect the electrical leads from the temperature sender unit, inlet manifold, carburettor and radiator fan thermal switch;

- disconnect the electrical leads from the temperature sender unit, inlet manifold, carburettor and radiator fan thermal switch;

- unbolt and remove the heated air box from the exhaust manifold;

- disconnect the exhaust downpipe from the manifold by unbolting the connecting flanges; support the exhaust system at the front end;

- pull free and remove the oil filler cap with breather hoses;

- extract the four screws and remove the rocker cover;

- unscrew and remove the four fixing bolts and lift away the rocker shaft assembly from the cylinder head;

- withdraw the pushrods, keeping them in their originally fitted sequence; a simple way to do this is to punch holes in a piece of card and number them 1 to 8 from the thermostat housing end of the cylinder head;

- remove the spark plugs;

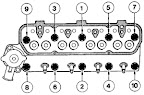

- unscrew the cylinder head bolts progressively in the reverse order to that given for tightening; remove the cylinder head.

Refitting:

- before refitting the cylinder head, remove every particle of carbon, old gasket and dirt from the mating surfaces of the cylinder head and block; do not let the removed material drop into the cylinder bores or waterways: if it does, remove it; normally, when a cylinder head is removed, the head is decarbonised and the valves ground in to remove all traces of carbon;

- before refitting the cylinder head, remove every particle of carbon, old gasket and dirt from the mating surfaces of the cylinder head and block; do not let the removed material drop into the cylinder bores or waterways: if it does, remove it; normally, when a cylinder head is removed, the head is decarbonised and the valves ground in to remove all traces of carbon;

- clean the threads of the cylinder head bolts and mop out oil from the bolt holes in the cylinder block; in extreme cases, screwing a bolt into an oil-filled hole can cause the block to fracture due to hydraulic pressure;

- if there is any doubt about the condition of the inlet or exhaust gaskets, unbolt the manifolds and fit new ones to perfectly clean mating surfaces;

- locate a new cylinder head gasket on the cylinder block, making quite sure that the bolt holes, coolant passages and lubrication holes are correctly aligned;

- lower the cylinder head carefully into position on the block;

- screw in all the bolts finger tight and then tighten them in four stages, in the sequence shown to the specified torque;

- refit the pushrods in their original order;

- lower the rocker shaft assembly into position, making sure that the rocker adjusting screws engage in the sockets at the ends of the pushrods;

- lower the rocker shaft assembly into position, making sure that the rocker adjusting screws engage in the sockets at the ends of the pushrods;

- screw in the rocker pedestal bolts finger tight; at this stage, some of the rocker arms will be applying pressure to the ends of the valve stems and some of the rocker pedestals will not be in contact with the cylinder head; the pedestals will be pulled down, however, when the bolts are tightened to the specified torque, which should now be done;

- adjust the valve clearances;

- refit the rocker cover; if the gasket is in anything but perfect condition, renew it;

- fit the oil filler cap and breather hose and the spark plugs; tighten these to the specified torque; they are of tapered seat type, no sealing washers being used;

- connect the exhaust downpipe and fit the heated air box;

- reconnect all electrical leads, vacuum and coolant hoses;

- reconnect the cables. Refit the battery (if removed) and reconnect the battery terminals;

- fit the air cleaner;

- refill the cooling system.

from Ford repair manuals